Innovative Solutions.

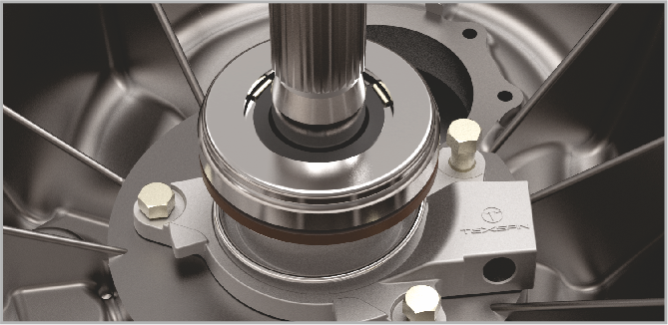

TEXSPIN® since its inception in 1961 has made a significant contribution to the automotive industry as a provider of unparalleled innovative solutions and products primarily for the automotive and other engineering industries. Bearings are “green products” that help reduce vehicle friction, pollution and fuel consumption. The strengths of TEXSPIN® are the tribology cultivated through bearing development, and the heat treatment, precision processing, and precision measurement required for bearing manufacturing.

The quest for new ideas and innovations to deliver specific solutions characterizes the continued growth of TEXSPIN®. This is supported by a Research and Development centre that ensures a constant stream of innovations to meet the high demands of the automotive industry. The R&D centre is equipped with the latest software technology to accurately simulate, analyse, validate, test and develop systems for various applications.

TEXSPIN® reputation and performance is based on extensive experience in design, engineering and technology development. The constant growth of TEXSPIN® is shaped by our own ideas and innovations.

TEXSPIN® R&D Center strives to be your development partner, aiming to build a symbiotic relationship with you and become your thinking partner in finding creative and innovative solutions to your engineering and technical challenges. TEXSPIN® specializes in customized technical products, components and systems. TEXSPIN® has developed stronger, energy-saving, lighter and more compact products by leveraging the strengths of these technical areas. By providing eco-friendly products, TEXSPIN® aims to increase customer satisfaction and achieve long-term growth.

TEXSPIN® uses its knowledge of vehicle systems to develop and manufacture solutions for conventional internal combustion engine, hybrid and all-electric powertrain customers. Additionally, hydrogen and fuel cell technology hold great promise for the future of transportation. The increasing automation of driving functions up to fully autonomous vehicles is increasing the demand for chassis applications.

Product design, analysis, prototyping, tooling, testing, validation and mass production are all used to bring your innovative ideas to life. These projects are managed in an integrated manner by experienced project managers who are an integral part of managing the activities, requirements, progress and solutions of each project.

With an evolving technology environment and consumer expectations, TEXSPIN® is committed to providing the most technologically advanced and well-designed products. As a result of all major research and development activities of TEXSPIN®, numerous patents are in the process of approval internationally, including Europe, USA, Indonesia, Japan, India, Malaysia and Mexico, 4 of which have already been granted.

21st century bearings are expected to perform better and extend their life under more demanding conditions. To achieve these high standards, TEXSPIN® continuously investigates new bearing designs and improves current ones using tribological and surface engineering methods to improve the microstructure. Recent years have seen the emergence of a new generation of highly sophisticated, extremely powerful and compact mechanical systems. The smooth operation of these systems depends on the performance and durability of plain and roller bearings. Downsizing can be faster in the current period while maintaining performance and effectiveness. Next-generation storage systems may be able to outperform expectations under more demanding and restricted working conditions.

The company’s pursuit of new and improved technology is strongly encouraged by the TEXSPIN® Test and Validation Center. Our state-of-the-art test bench allows detailed analysis of bearings using specially developed test solutions. These test solutions range from driving dynamics to functional behaviour of application and their components, geometric behavior to operational stability. The best way to estimate actual bearing life and reliability is the long-used Weibull analysis in TEXSPIN®s Reliability Centre. Bearing testing focuses on vehicle level and in-house test bench testing. To make our products more effective, we always learn from experimentation.

TEXSPIN® has a distinct identity of providing end-to-end solutions for all customers’ technical needs. TEXSPIN® has a dedicated, highly skilled team and state-of-the-art facilities for the design and manufacture of specialty machinery, automated assembly lines, and test and verification equipment. With over 60 years of experience and over 1500 experienced employees engaged in manufacturing and sales, TEXSPIN® is committed to a culture of quality and innovation, using quality systems such as IATF — 16949: 2016, striving to exceed the high standards of the automotive industry.

Contact us:

Email: mail@texspin.com

visit: www.texspin.com